Elongation at break

the layer shows an elongation at break in the order of 0.5 to 1.0 percent after measuring foils using the dome method.

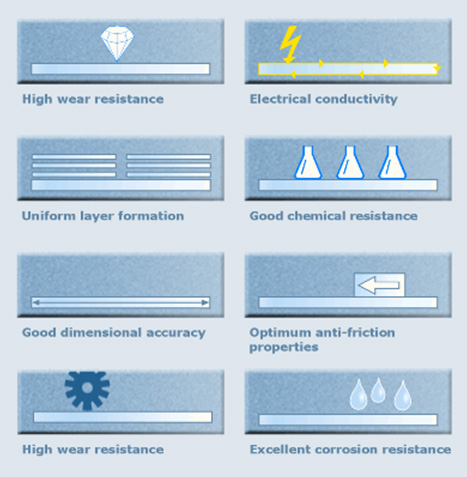

Abrasion

abrasion amounts to ≤ 35 mg. after 1,000 revolutions in the Taber-Abraser test using CS 10 wheels.

Hardness

the hardness amounts to about 570 HV 0.05; heat treatment increases the hardness up to about 1,000 HV 0.05.

Corrosion resistance

for instance, a layer with a thickness of 40 µm and roughness of Rz von ≤ 1 µm applied on a St 52

base material resists more than 200 hours in the acetic acid salt-spray test according to DIN EN ISO

9227. In the Kesternich test according to DIN 50 018, the same layer can resist for more than 3

cycles SFW 0.2.